Ultimate Guide to Electronic Prototyping: From Concept to Product Development

Electronic prototyping is a vital stage in the development of electronic devices, enabling engineers and innovators to transform concepts into functional prototypes. These prototypes serve as early models to validate designs, test functionalities, and gather crucial feedback before proceeding to full-scale production.

Introduction to Electronic Prototyping

Electronic prototyping involves creating preliminary models of electronic devices to evaluate design concepts and functionality. It bridges the gap between idea conception and market readiness by allowing iterative refinement based on testing and user feedback.

Key Steps in Electronic Prototype Development

Conceptualization and Design

The process begins with conceptualization, where ideas are brainstormed and initial designs are sketched out. Engineers analyze feasibility and define project goals to establish a clear direction for development.

Component Selection

Choosing the right electronic components is essential for prototype success. Factors such as performance requirements, power consumption, and compatibility influence component selection. Engineers leverage their expertise to ensure components align with project specifications and budget constraints.

Circuit Design and Simulation

Circuit design involves creating schematic diagrams that illustrate how components will connect and function together. Simulation tools such as SPICE simulate circuit behavior under different conditions, helping to optimize designs and predict performance outcomes.

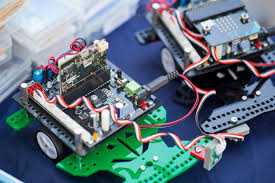

PCB Layout and Design

Printed Circuit Boards (PCBs) are integral to electronic prototypes, providing a physical platform for component assembly and connectivity. Designing PCBs involves considerations like size, layers, and routing to optimize functionality and manufacturability.

Assembly and Testing

Components are assembled onto the PCB using soldering techniques that ensure reliable electrical connections. Functional testing follows assembly, where engineers validate prototype performance against design specifications. Iterative testing and debugging refine the prototype for enhanced functionality and reliability.

Software Development

Prototype Electronics often require embedded software to control operations and interface with users. Engineers program microcontrollers or processors, integrating software seamlessly with hardware components. User interface (UI) design focuses on creating intuitive interactions through usability testing and iterative design improvements.

Integration and Iteration

Integrating hardware and software components ensures seamless functionality and compatibility. Engineers address system integration challenges and gather user feedback to drive iterative improvements throughout the development cycle.

Regulatory Compliance and Standards

Meeting regulatory standards such as CE (Conformité Européenne) and FCC (Federal Communications Commission) is crucial for market readiness. Prototypes must undergo rigorous testing to ensure compliance with safety and environmental regulations, facilitating smoother product certification.

Cost Considerations

Effective budgeting is essential to manage prototype development costs efficiently. Engineers estimate costs accurately, balancing investments in quality components and manufacturing processes to optimize value without compromising on performance or reliability.

Scaling from Prototype to Production

Transitioning from prototype to mass production requires strategic planning and execution. Manufacturers streamline production processes while maintaining product integrity and performance standards. Addressing scalability challenges early accelerates time-to-market and enhances competitiveness in the marketplace.

Case Studies and Examples

Examining successful electronic prototypes offers valuable insights into best practices and innovation strategies. Real-world examples across diverse industries highlight how prototypes evolve into market-ready solutions through iterative development and user-centric design.

Future Trends in Electronic Prototyping

Advancements in rapid prototyping technologies continue to revolutionize electronic product development. Innovations in IoT (Internet of Things) and AI (Artificial Intelligence) integration expand possibilities for smart, interconnected devices, driving ongoing innovation and enhancing product capabilities.

FAQs

- What is electronic prototyping? Electronic prototyping involves creating preliminary models of electronic devices to validate designs and functionalities before full-scale production.

- Why is circuit design important in electronic prototyping? Circuit design defines how electronic components will connect and function together, crucial for optimizing performance and ensuring prototype functionality.

- How does regulatory compliance impact electronic prototype development? Regulatory compliance ensures prototypes meet safety and environmental standards, facilitating market entry and product certification.

- What role does software development play in electronic prototyping? Software development integrates with hardware to control operations and interface with users, enhancing prototype functionality and usability.

- Why is iterative testing and feedback important in prototype development? Iterative testing and user feedback refine prototypes, identifying and addressing issues early to enhance performance and user satisfaction

Conclusion

Electronic prototyping is a dynamic process that empowers innovators to translate ideas into tangible products. By embracing prototyping as a strategic tool, engineers and developers refine designs, validate functionalities, and deliver solutions that meet evolving market demands and consumer expectations.